1. Installing Odin on a new Process

Installing Odin on a new process goes as follows:

- Build Odin on each machine that will be used by the process

for data acquisition, control, and monitoring purposes.

- Configure the part of Odin that runs on each machine (Bioprocess,

Supervisor or User Interface).

- Write or adapt startup scripts, shutdown scripts and IOR servers.

1.1 Building Odin

If your are using Ubuntu we recommand using the ‘install-Ubuntu.sh’

script that make all the job for you, just let it guid you through the different steps.

This install process require an internet connection.

Building Odin is done by following the instructions available in

the README file in the top directory. The README file also contains

troubleshooting instructions.

Under UNIX systems, it is generally as simple as installing dependencies,

and then executing

./configure

make

Alternatively, a ‘make_odin.sh’ file is provided that builds odin,

setting up the appropriate environment variables.

To use it, simply execute

./make_odin.sh

Dependencies names are provided for Ubuntu distributions.

Here is a list suitable for Ubuntu 8.04 to Ubuntu 10.04 :

- build-essential

- gfortran

- python-dev

- qt4-dev, libqt4-dev, qt4-dev-tools

- omniidl4, omniorb4, libomniorb4-dev

- pvm-dev

- libx11-dev, libxt-dev

- libssl-dev

- libxext-dev

- libboost-dev

- libxml2-dev

- gettext

- libblas-dev

- liblapack-dev

- libpcre3-dev

- libxmu-dev

A few precisions about these dependencies:

- build-essential is a set of packages needed to compile some code on ubuntu.

- gfortran, pvm-dev, libx11-dev, libxt-dev, libxext-dev, libxml2-dev, gettext,

libblas-dev, liblapack-dev, libpcre3-dev, libxmu-dev are needed by Scilab.

- qt4-dev, libqt4-dev, qt4-dev-tools are needed by the User Interface.

- omniidl4, omniorb4, libomniorb4-dev supply the OmniORB library and

IDL compiler (OmniORB is a CORBA broker). This library allows different parts

of the application to be run on different machines connected over a network.

- python-dev, libssl-dev are needed by OmniORB (CORBA support).

- libboost-dev is needed for a few instances of boost::shared_ptr,

but we aim to get rid of this dependency.

Under Ubuntu, the dependency library-name can be installed

by executing

sudo apt-get install library-name.

For instance, installing libraries libboost-dev and

libssl-dev can be done by executing

sudo apt-get install libboost-dev libssl-dev

A note about libmodbus:

The TES and Alto processes (code that acquires data and sends orders to/from

TES and Alto modules supplied by Leroy Automation) requires that libmodbus

be installed on your machine. This library is usually not supplied as a

package by common Linux distributions, so it must be installed from source.

An archive (‘libmodbus-2.0.0.tar.gz’) is provided in the ‘contrib’

directory. Extract it to a place of your choosing, then run

./configure

make

sudo make install

C++ compiler

Odin has been built and tested with the g++ compiler.

Under Ubuntu, the packet build-essential provides g++.

Install it by running sudo apt-get install build-essential.

1.2 Setting up the Bioprocess

This chapter describes the Bioprocess setup.

Connecting Odin to a physical process entails choosing the appropriate

hardware drivers, configuring those drivers and making sure that

the Bioprocess is accessible to the outside world.

1.2.1 Hardware drivers

Hardware 'drivers', such as TES boards drivers, MccDaq boards drivers,

and the Simulator acquire data from the "real world" and carry orders.

To an Odin installation, a set of inputs (Sensors) and outputs (Actuators)

that use the same driver is known as a "Bioprocess".

Bioprocess configuration is defined by the driver implementer.

To install Odin on a bioprocess, you should take note of all relevant

aspects of your setup (serial ports names, IP addresses, sensor

and actuator names and location on the acquisition boards...).

1.2.2 Bioprocess Configuration

Configuring a Bioprocess mostly means mapping names (a 'name' is

an UID in Odin parlance) to inputs/outputs on an acquisition board,

or a simulator, and setting up communication details (name of a serial port,

IP address of an Alto module) and choosing the data acquisition period if

applicable.

Each Bioprocess implementor is free to choose its configuration

file format (altough some factoring should be envisaged), and in some cases

(e.g. the Simulator) we dispense with a configuration file (the Simulator

configuration is described directly in the Scilab code).

1.2.2.1 Example: the TES process

TES boards are data I/O modules that are connected over a Modbus network.

These boards provide digital and analog inputs and outputs. To set up a TES

module with Odin, you should:

- Create (or modify) the configuration file ‘tes-settings.xml’.

- Run the ‘tesProcess’ executable.

Let's cover the ‘tes-settings.xml’ file in more detail:

look at the example file, and then read below for explanations.

<!DOCTYPE tes-settings>

<tes-settings>

<version>1</version>

<serial-device>/dev/ttyS1</serial-device>

<sample-interval>30</sample-interval>

<sensor>

<type>Gen1w</type>

<slave>2</slave>

<!-- third analog input --> <!-- addresses are written in base 10 -->

<address>6</address>

<device-uid>ext-tempIn</device-uid>

<group>ext</group>

<unit>C</unit>

<!-- in this example, a raw value of 200 is a temperature of 0 degrees Celsius, and a raw value of 1023 is a temperature of 100 degrees Celsius -->

<scaling>

<xmin>200.0</xmin><ymin>0.0</ymin>

<xmax>1023.0</xmax><ymax>100.0</ymax>

</scaling>

<domain>

<min>-10.0</min>

<max>65.0</max>

</domain>

<validityPeriod>3600</validityPeriod>

</sensor>

<sensor>

<type>OnOff</type>

<slave>2</slave>

<lane>1</lane>

<device-uid>ext-pumpStatus</device-uid>

<group>ext</group>

</sensor>

<sensor>

<type>Gen2w</type>

<slave>1</slave>

<!-- input 0 time counter --> <!-- addresses are written in base 10 -->

<base-address>1071</base-address>

<device-uid>ext-pumpTime</device-uid>

<group>ext</group>

<unit>s</unit>

<scaling>

<xmin>200.0</xmin><ymin>0.0</ymin>

<xmax>1023.0</xmax><ymax>102.3</ymax>

</scaling>

<validityPeriod>3600</validityPeriod> <!-- one hour -->

</sensor>

<actuator>

<type>OnOff</type>

<slave>1</slave>

<lane>2</lane>

<device-uid>in-pumpCommand</device-uid>

<group>in</group>

<unit>None</unit>

</actuator>

<actuator>

<type>Gen1w</type>

<slave>1</slave>

<address>25</address> <!-- fifth analog output -->

<device-uid>in-heatCommand</device-uid>

<group>in</group>

<unit>None</unit>

<scaling>

<xmin>0.0</xmin><ymin>0.0</ymin>

<xmax>1023.0</xmax><ymax>1023.0</ymax>

</scaling>

</actuator>

</tes-settings>

version is a version number for future compatibility needs.

It is currently always set to 1.

serial-device is the full name (incl. path) of the serial device

that you want to use to communicate with the TES modules, e.g.

/dev/ttyS1 or /dev/ttyUSB0.

sample-interval is the period of the polling loop, ie the sensors

will be polled every sample-interval seconds.

sensor describes a Sensor (unsurprisingly).

The common attributes for Sensors are:

-

type - describes the type of the data that will be read - one

of Gen1w, Gen2w or OnOff.

-

slave - the Modbus slave number (1-based, 0 means broadcast and

is explicitly disallowed).

-

device-uid - the Unique Identifier that will be used to refer

to this Sensor within Odin. For instance, you will use it to get the latest

data point within Odin Observers and Controllers, or to request historical

data from the Supervisor, or to plot the values of this Sensor over time

within the User Interface.

-

group - name of the group the sensor belongs to.

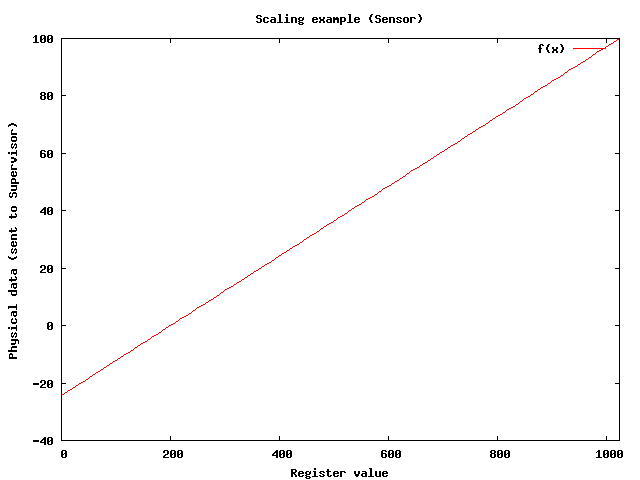

Gen1w (Generic One Word) and Gen2w (Generic Two Words) Sensors

In addition to the common Sensor attributes,

Gen1w and Gen2w sensors also have the following attributes:

OnOff Sensors

In addition to the common Sensor attributes, OnOff sensors also have

the following atributes:

-

lane - 0-based index of the digital input to be read.

OnOff sensors will always return 0 or 1. Scaling is not available.

The domain attribute is (obviously) not relevant, and does not exist

for OnOff sensors.

actuator describes an Actuator.

The common attributes for Actuators are:

-

type - Type of the data that will be written - one

of Gen1w or OnOff.

-

slave - Modbus slave number (1-based, 0 means broadcast and

is explicitly disallowed).

-

device-uid - a Unique Identifier that will be used to refer

to this Actuator within Odin. For instance, you will use it to request

historical data from the Supervisor, or to plot the values of this

Actuator over time within the User Interface.

Gen1w Actuators

In addition to the common Actuator attribues, Gen1w actuators

also have the following attributes:

-

address - Address of the register to be written to, in base 10.

-

unit - Unit of the order (e.g. celsius degrees,

liters per hour)...

-

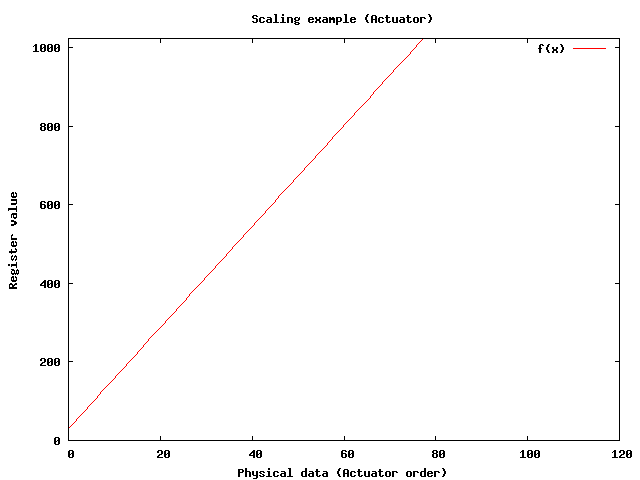

scaling - an afine transform that converts the Actuator order

(normally a physical data) to a Modbus register value.

For instance, if we have:

<scaling>

<xmin>30.0</xmin><ymin>0.0</ymin>

<xmax>100.0</xmax><ymax>900.0</ymax>

</scaling>

then the conversion will go like this (register values are integers

between 0 and 1023):

The resulting floating point number will be rounded to the closest integer

(since register values are integers).

Note that while the Sensor scaling converts a Modbus sample value

(proportional to a current or voltage) to a physical value, the Actuator scaling

converts a physical value (e.g. effluent flow rate in liters per second)

to a Modbus sample value (proportional to a current or voltage)

OnOff Actuators

In addition to the common Acutator attributes, OnOff actuators

also have the following attributes:

-

lane - 0-based index of the digital output to be written to.

1.2.2.2 Example: the Alto process

Alto modules are very close to TES boards, but they communicate over

Modbus/TCP (i.e. over an IP network). These modules are also configurable over

HTTP. To set up an Alto module with Odin, you should:

- Create (or modify) the configuration file ‘alto-settings.xml’.

- Run the ‘altoProcess’ executable.

The ‘alto-settings.xml’ is very similar to the file

‘tes-settings.xml’, so we will just mention the important differences:

- The serial port name is replaced by an host name or IP address

(e.g.

<host>10.0.0.100</host>)

- the 'slave' in classical Modbus vocabulary is replaced by a

'Unit Identifier' (noted as 'ui' in the configuration file). It is zero-based

(whereas in classical Modbus a zero slave means 'broadcast' and is not to be

used within Odin). I'm not sure whether the UI has a lot of

practical utility when using Alto modules because these modules normally

have distinct IP addresses, which is enough to identify them.

Leave it to zero if you are unsure.

Please refer to the example file located in ‘bioprocess/altoProcess’.

1.2.2.3 Note about Alto and Tes Processes

Since the hardware support for both these module types is provided by

libmodbus and there is a lot of commonality between them, it would

be a good idea to merge them (and generalize TesProcess and AltoProcess

into a “ModbusProcess” module). It would remove duplicated code and

be more generic (“OnOff” sensors/actuators should be replaced by

“One bit” (masked) sensors and actuators).

1.2.2.4 Example: the Simulator process

The Simulator process is, as the name implies, a virtual process.

Its sensor values are computed by a Scilab script that is

called regularly, passing it the Actuator orders that were computed by

active Controllers.

Using the Simulator process is straightforward: simply place an appropriate

Scilab script in the ‘simulator’ directory and run the ‘simProcess’

executable, passing it the name of the Scilab script without the extension

(e.g. if the file is called ‘sim.sce’, you should run

./simProcess sim).

A simulator example exists at ‘simulator/sim.sce’. It simulates an

anaerobic digestion process using the model AMH1.

Other simulated systems implementations exist in the same directory,

but at this time (2008-OCT-06), ‘sim.sce’ is the only one that

has been validated. Of course, validating other simulators is a

useful activity.

1.2.3 Making the Bioprocess accessible to the Supervisor

If the Supervisor and the Bioprocess are colocated on the same machine, no

particular action is needed (see the startup script configuration for

more information).

If the Supervisor and the Bioprocess are on different machines, they

must be somehow able to exchange messages. OmniORB (the CORBA library

used by Odin) provides a transport layer over TCP/IP networks, so you

are advised to connect both machines to such a network.

Assuming you are using the former, please see "Setting up IOR servers" which

describes a convenient way to expose a CORBA reference

(each reference being served on a distinct port by the host machine).

You may opt to design your own IOR exchange mechanism (using e-mail,

a shared space, another RPC system...) but this is more involved.

1.3 Configuring the Supervisor

The Supervisor is configured by setting options in the file

‘supervisor.cfg’.

This files comprises the following parameters:

speedFactor

sleepTimeMs

Set speedFactor to 1 unless Simulator is used

(in which case it should be

set to the same value as the corresponding Simulator parameter).

sleepTimeMs is the main loop sleep time, i.e. approximate Observer and

Controller computation period (typically a few seconds to a few minutes),

expressed in milliseconds. It cannot be less than 1000 milliseconds

(one second).

The user then places the appropriate Observer and Controller files in the

corresponding directories to have them run by the Supervisor. These files

are executed as follows:

- Observers in filename lexicographical order

- Controllers in filename lexicographical order

For instance, if the directory structure of your installation

looks like this:

+-odin/

|

+-controllers/

| |

| +-01_ctr_dcoqm.sce

| |

| +-02_ctr_another.sce

|

+-observers/

|

+-obs_xc.sce

|

+-obs_z.sce

The order of execution during a control loop will be:

- ‘obs_xc.sce’

- ‘obs_z.sce’

- ‘01_ctr_dcoqm.sce’

- ‘02_ctr_another.sce’

We recommend adopting the convention of prefixing observer and controller

filenames with an integer to enforce execution order (as shown here with

the controller filenames).

1.4 Configuring the User Interface

The Synoptic view is the only part of the User Interface that

needs to be configured by the Installer.

The Synoptic configuration is described in ‘synLayout.xml’.

Here is an example of ‘synLayout.xml’ possible contents:

<!DOCTYPE synoptic-layout>

<!-- edit this file to configure the synoptic view panel of Odin or to adapt it to a new process -->

<!-- coordinate system: (0,0) at the top left of the panel, x axis points to the right, y axis points downwards -->

<!-- to customize: change "schematic-path" to the relative or absolute path of the schematic background image, and add, modify or remove "item" blocks -->

<synoptic-layout>

<version>1</version>

<schematic-path>./synoptic/process_lbe_syn.png</schematic-path>

<data-items>

<item>

<uid>ext-tempIn</uid>

<label>External effluent temperature</label>

<coord><x>210.0</x><y>392.0</y></coord>

</item>

<item>

<uid>alim-phIn</uid>

<label>External effluent pH</label>

<coord><x>536.0</x><y>390.0</y></coord>

</item>

<item>

<uid>gas-co2Gas</uid>

<label>Carbon dioxide flow</label>

<coord><x>910.0</x><y>145.0</y></coord>

</item>

</data-items>

</synoptic-layout>

1.5 Setting up IOR Servers

An IOR (Interoperable Object Reference)

is a reference to a CORBA object that can be stringified.

Within Odin, the installer (i.e. you) is responsible for making

sure that the different parts of the system (Bioprocesses, Supervisor

and User Interfaces) know about each other. This is done by exchanging

their IOR.

The Bioprocesses (up to N instances per system) and the Supervisor

(one unique instance per system) export their IOR,

respectively in the files ‘bioprocess.ref’ and

‘supervisor.ref’.

Two steps are necessary to have all parts of the system communicating:

- The Supervisor must get a reference to each of its Bioprocesses

(using the utility ‘addpc’).

- The User Interface must get a reference to the Supervisor.

IOR server templates are provided in the ‘util’ directory.

These are ‘bp-ior.sh’ (serves a Bioprocess reference) and

‘sup-ior.sh’ (serves a Supervisor reference).

After running these scripts on the host machine, you may retrieve the IORs

from remote machine, for instance by running

‘nc [host address or name] 8888’

To use these scripts, the ‘socat’ utility needs to be installed on the

serving machine. Use your favorite package manager to install it.

Non-distributed startup script example:

#!/bin/bash

# This is a *sample* ODIN startup script. Edit and adapt to your needs.

./simProcess sim&

sleep 2

./supervisor-bin&

sleep 3

./util/addpc `cat supervisor.ref` `cat bioprocess_sim.ref`

Distributed startup script example:

# Sur une machine d'acquisition (192.168.1.10)

./mccDaqProcess mcc&

sleep 2

./util/bp-ior

# Sur une autre machine d'acquisition (192.168.1.13)

./tesProcess tes&

sleep 2

./util/bp-ior

#Sur la machine de supervision (192.168.1.9)

./supervisor-bin&

sleep 2

./util/addpc `cat supervisor.ref` `nc 192.168.1.10 8888`

sleep 2

./util/addpc `cat supervisor.ref` `nc 192.168.1.13 8888`

./util/sup-ior

#Sur une machine de supervision

nc 192.168.1.9 9999 > sup.ref

./ui/ui

This document was generated by Fabien Dilet on July, 21 2010 using texi2html 1.78.